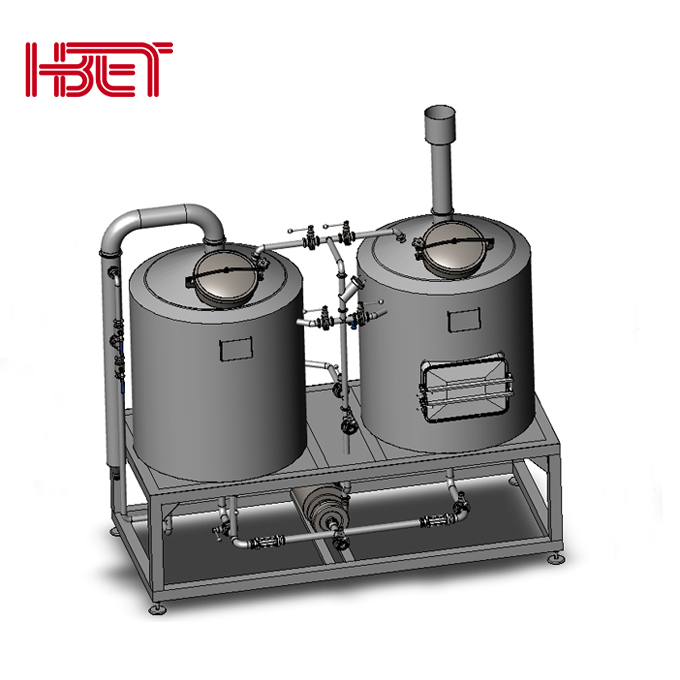

200L Nano brewery mini brewing setup

- HBETBREW

- Shandong

- 30days

- 100sets/month

200L nano brewery mini brewing setup is a good choice for restaurants, bars, and hotels to serving beer to customers directly with less installation space and investment.

200L Nano brewery mini brewing setup

200L nano brewery mini brewing setup is a good choice for restaurants, bars, and hotels to serving beer to customers directly with less installation space and investment.

Main Specifications of 200L nano brewery mini brewing setup

Material is 304 stainless steel – polished (red copper as options)

Output >2HL wort per batch

Composed by Two vessels 200L Brewhouse + fermenters/Brite tanks+malt mill + Cooling system + CIP cleaning system+Control panel

Installation space needed 20m2

200L nano brewery mini brewing setup configuration list:

Malt mill | 1. Capacity: 150kg/h 2. Carbon steel/SUS304 |

Mash+Lauter Tank | 1. Effective volume=200L 2. Atmospheric pressure lid |

Kettle+Whirlpool Tank | 1. Effective volume=200L 2. Atmospheric pressure lid |

Hot water tank | 1. Effective volume=400L 2. Atmospheric pressure lid 3. Electric element:18KW 4. Temperature Probe:PT-100 |

Wort Pump/Hot water pump | 1.Flow: 1m3/h |

Hops Filter & Heat Exchanger | 1.Y type hops filter |

Fermenters | 1. Effective volume 200L 2. Pressure flange manway 3. Double layers with cooling jacket and insulation 4. 60°Cone design 5. Complete fittings |

Glycol cooling system | 1. Glycol water tank 200L 2. Chiller 2HP 3. Glycol water pump 4. Cooling pipelines and fittings |

CIP cleaning system | 1. Disinfection tank 50L 2. Caustic tank 50L 3. Cleaning pump 4. Trolley 5. Control panel SUS |

PID Controller | 1. SUS 304 Material cabinet 6. TC connection, rotatable design 7. Fermenters, glycol water tanks temperature control |

Our nano brewery advantage:

- Equipment design as per customer brewing method and brewing beer types can make beer highest to 33 Plato.

- All Construction uses high-quality SUS 304 food-grade stainless steel, all pipes are SUS304, perfect 3mm inner shell and 2mm outer shell.

- All tanks are equipped with specially designed jackets to ensure heating and cooling efficiency. Both cone top and shell bottom have jackets, exchanging area are big enough.

- The headspace of our tanks is much bigger, the total volume does not include the cover headspace.

- 100%TIG welding process to weld the tank, jackets welding are all full welding by water, uniform dimpled cooling jacket to ensure no leaking and long life, welds passivated.

- Overall mirror polishing, polishing 6 times to make Ra 0.4um mirror finish, can clean 360° without dead ends.

- Jacket testing 12 hours with air and water, jacket testing pressure is 5Bar, internal shell testing pressure is 4Bar, and before packing we will also have 48hours of water testing.

- Strict quality control and process inspection & testing system, which all the testing record will show on our data late with the tanks shipping, with checking the list and serial numbers to track.

- Insist on high-end product line to manufacture all tanks, components like chiller, exchanger, steam boiler and Schneider/ABB electronics control systems adopt international brands to ensure quality and convenient after-sales.