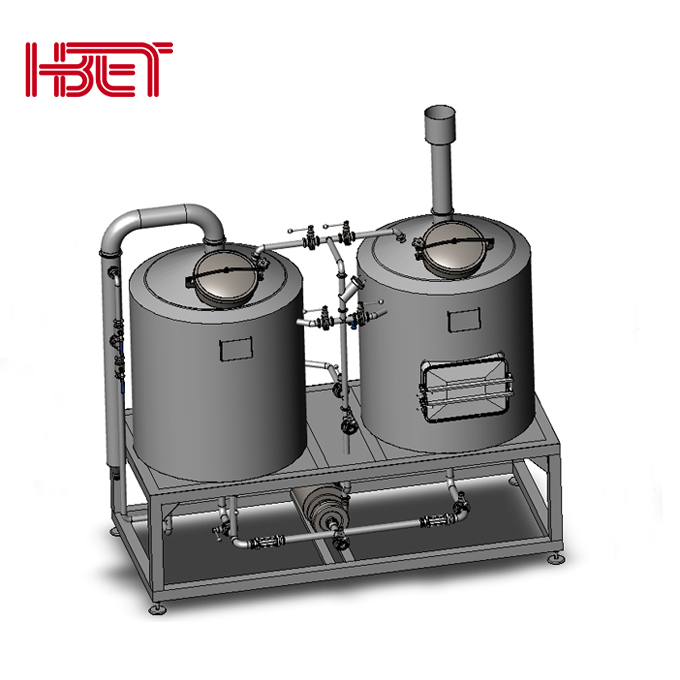

Home brewing setup three pots brewhouse home brew pilot brewery

- HBETBREW

- Shandong

- 30working days

- 100sets/month

This is our new design of three vessels brewhouse for home brewing set up, it can be used as home brew or pilot brewery, which is a fully hard-piped electric RIMS system. This new design puts three vessels or pots on a stainless steel skid, all of the critical process valves directly in front of the brewer. The included control panel manages all the heating elements, pump, and temperature changes. All three vessels are double layers design with insulation.

Home brewing setup three pots brewhouse home brew pilot brewery

This is our new design for three vessels brewhouse, it can be used as home brew or pilot brewery, which is a fully hard-piped electric RIMS system. This new design puts three vessels or pots on a stainless steel skid, all of the critical process valves directly in front of the brewer. The included control panel manages all the heating elements, pump, and temperature changes. All three vessels are double layers design with insulation.

The system has a precision-milled false bottom instead of a punched one, allowing a faster filtering and get clearer wort. The mash tun/lauter tun has been designed with a unique grain-out door for quick tipping and dumping of the spent grains after filtering.

This three vessels brewhouse is perfect for larger homebrewers or professionals who might be looking to start their own brewery. This nano brewing setup is capable of producing anywhere from 30L-200L (7gallon -50gallon) batches in a single run.

Each size comes with precision-milled stainless steel false bottom, stainless steel wort chiller, stainless steel pump, mash paddle, stainless skid, stainless steel control panel and other matched components.

Let me take 150L capacity as an example to introduce the configuration list of this home brew setup:

Hot water tank:

Effective volume 150L

Gross volume 227L

Material: Stainless steel 304, thickness 2.0/2.5mm

Insulation: aluminum silicate, thickness: 65mm

Tank dimension: diameter 720mm, cylinder height 950mm

Lid place on top of tank and cone 160°at bottom

Operating temperature 10-90℃

Design temperature 0-100℃

Electric heated, heating power 4KW

PT 100 as temperature measurement

CIP in-situ cleaning, pressure 1.5bar

Place on the overall skid

Inner surface pickling and passivation treatment, Ra≤0.6μm

External surface treatment: The outside surface brushed board surface or head polished, Welding seam polished with width 40mm.

Mash tun/lauter tun:

Effective volume 150L

Gross volume 227L

Material: Stainless steel 304, thickness 2.0/2.5mm

Insulation: aluminum silicate, thickness: 65mm

Tank dimension: diameter 720mm, cylinder height 950mm

Lid place on top of tank and cone 160°at bottom

Operating temperature 10-100℃

Design temperature 0-105℃

Manway on side of tank 230*330mm

PT 100 as temperature measurement

CIP in-situ cleaning, pressure 1.5bar

Place on the overall skid

Inner surface pickling and passivation treatment, Ra≤0.6μm

External surface treatment: The outside surface brushed board surface or head polished, Welding seam polished with width 40mm.

Kettle/Whirlpool:

Effective volume 150L

Gross volume 227L

Material: Stainless steel 304, thickness 2.0/2.5mm

Insulation: aluminum silicate, thickness: 65mm

Tank dimension: diameter 720mm, cylinder height 950mm

Lid place on top of tank and cone 160°at bottom

Operating temperature 10-110℃

Design temperature 0-140℃

Electric heated, heating power 4KW

PT 100 as temperature measurement

CIP in-situ cleaning, pressure 1.5bar

Place on the overall skid

Inner surface pickling and passivation treatment, Ra≤0.6μm

External surface treatment: The outside surface brushed board surface or head polished, Welding seam polished with width 40mm.

Wort pump

Flow 1m3/h, lift 15m

Power 0.55

Power supply: 3-380V, 50Hz;

Sanitary grade open impeller

Material SUS304

Plate heat exchanger

Heat exchanger area: 1m2

Plate material SUS316

Supporting material SUS304

Frame wrapped SUS304

Two sections suspension type

Design pressure: 8bar

Test pressure: 10bar

Design temperature: 110 °C

SUS Control panel:

Low-voltage Schneider

Power supply: single phase, 220V, 50HZ

Brewhouse temperature display

Wort pump on/off &VFD controlled

Hot water tank/Kettle heating on/off, temperature controlled by manual and automatic

If you need further more information about this home brewing setup, feel free to contact us.