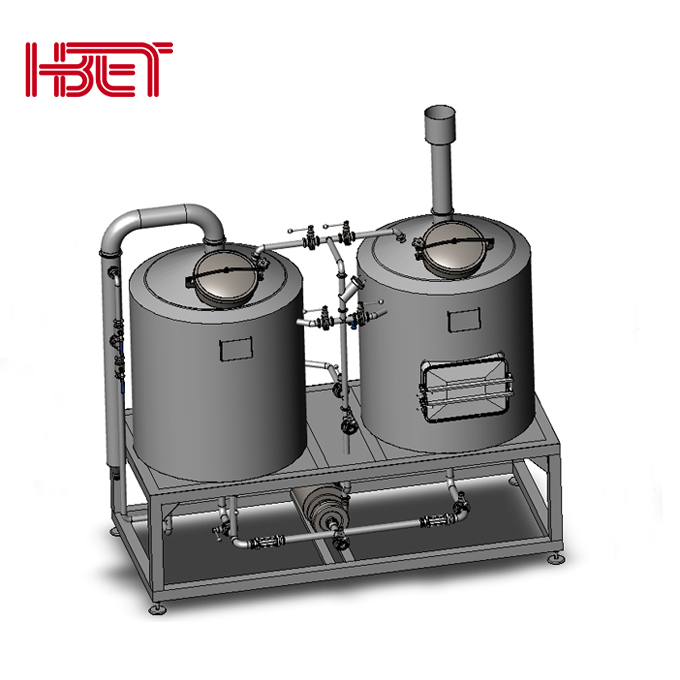

50L Micro Home Brew Equipment

- HBET

- Shangdong, China

- Within 30days

- 50sets/month

The capacity of this home brew equipment is between home brewing and small beer brewing, which not only meets the brewing needs of home brewing enthusiasts, but also provides a transition for home brewers from manual brewing to commercial brewing.

Thhis home brew equipment has a simple design structure, is convenient for operation, has a small footprint, and is convenient and flexible to move.

This home brew equipment can be used not only for home brewing, but also for brewing recipe testing of brewery equipment.

50L Micro home brew equipment

The capacity of this home brew equipment is between home brewing and small beer brewing, which not only meets the brewing needs of home brewing enthusiasts, but also provides a transition for home brewers from manual brewing to commercial brewing.

Thhis home brew equipment has a simple design structure, is convenient for operation, has a small footprint, and is convenient and flexible to move.

This home brew equipment can be used not only for home brewing, but also for brewing recipe testing of brewery equipment.

Configuration of Home brew equipment

No. | Components | Standard Specification |

1 | Miller | Abrasive disc type Power:1.1kw; capacity: 80kg/h Separated control switch Power supply must be 220V 50HZ 1 PHASE. |

2 | Brewhouse | SUS 304; Gross capacity: 60L; Useful capacity: 50L; Inner-jacket (SUS304), thickness: 2.0mm; External-Jacket (SUS304), thickness: 1.5mm; Heating tube inside for heating Inside with filter vat; Manhole dimension: diameter 600mm; CIP spraying ball; Insulation: Polyurethane-thickness: 50mm. |

3 | Wort pump | Flow: 1m³/h, centrifugal pump,SUS304; |

4 | Filter on pipelines | SUS304 |

5 | Fementers

| Gross capacity: 65L; Useful capacity: 50L; Inner thickness:2.5mm; Cladding thickness:1.5mm; Insulation PU: 50mm; Polishing to Ra0.8µm; 60°cone design, glycol water cooling belt; Top flange manway; SS feet and legs |

6 | Glycol tank | Gross volume: 50L; Jacket thickness: 2.5mm; outer thickness: 1.5mm; Insulation PU: 50mm; The percent of glycol to water: 1:2 |

7 | Chiller | Model type:1HP; Refrigerant: R404A; power: 0.75kw: |

8 | Glycol water transfer pump | Flow: 13L/min; Lift: 5m; |

9 | Control panel | Placed on the bottom of brewhouse Control box material is SUS 304 Used for turn on/off the pumps, fermenters and glycol tanks’s temperature control Heating element turn on/off |