The process of craft beer equipment brewing

The process of craft beer equipment brewing:

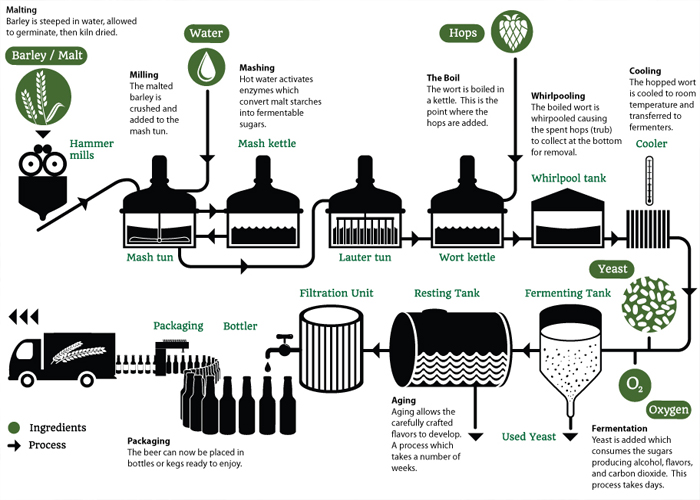

The production process of the craft beer equipment mainly includes four kinds of mashing process, fermentation process, filtration process and sterilization process.

1, saccharification process of beer equipment brewing

Potatoes and cereals, as well as wild and raw plant raw materials are subjected to pressure cooking, and the starch is gelatinized to be dissolved, but it cannot be directly decomposed by yeast and fermented to produce alcohol. Therefore, after the cooking of the gelatinized mash, before the fermentation, it is necessary to add a saccharifying agent to change the dissolved starch into a sugar which can be fermented by the yeast, such a process of converting starch into sugar. It is called saccharification. The saccharification process is the process of amylase or acid hydrolysis, which saccharifies the starch into a fermentable sugar. In addition, the saccharifying agents commonly used in alcohol production are malt and koji. In China, koji is widely used as a saccharifying agent.

2. Fermentation process of beer equipment brewing

Glucose is hydrolyzed by alcoholase to form ethanol to form a fermentation broth. Moreover, in the fermentation process of the wine, a large variety of microorganisms and aroma substances are produced in the Dianchi Lake, and slowly deep into the mud. Infiltration, it becomes a rich natural source of fragrance. The longer the age of the cockroach, the more microbes and aromas, the stronger the scent of the wine; the new sputum is less and less balanced, and there are also unstable factors in the metabolism of new aging, so brewing The wine will have a heavy new smell. Due to the long time of use, the old loach is beneficial to the continuous purification and enrichment of microorganisms. The wine produced is getting better and better, and it is getting more and more fragrant. Therefore, the longer the used time, the better the wine produced in Dianchi.

3. Filtration process of beer equipment brewing

In ancient times, the filtration technique of wine was not mature, and the beer was turbid, called white wine or turbid wine. Nowadays, the development of the filter filter with high filtration efficiency and high efficiency has been vigorously promoted by the country and the outside world. The promotion and application of the beer filter makes the beer, wine, yellow wine and other transparent, clear and stable, and improves the appearance of the finished wine. This not only reflects the high quality of the beer but also induces consumers' desire to drink.

4, sterilization process of beer equipment brewing

Brewed beer is made from food, fruit, etc. It has a non-Changfeng. Rich camp. It contains ingredients such as amino acids, proteins, vitamins and oligosaccharides that are beneficial to human body. However, due to the production and processing of wine, bacteria and bacteria are inevitably present on the air and the container, and the wine itself also produces a large number of yeasts, enzymes, etc. in the process of fermentation, in order to make the brewed wine store aroma, Bao. The long-term storage of the wine is not deteriorating, the key is to do the sterilization work.

There are many methods for sterilization, such as ultraviolet sterilization, high temperature sterilization, ozone sterilization, membrane filtration sterilization, and the like. At present, the rice wine enterprises in the country usually adopt high-temperature sterilization method, which has low cost, simple operation and good sterilization effect. Although several other methods can achieve the purpose of sterilization, but the cost is relatively high, and some methods will also affect the taste of the wine and the special flavor of the yellow beer.