1000 Liter Mash Tun Lauter Tank Brew Kettle

- HBET

- Shangdong, China

- Within 30days

- 50sets/month

Brewhouse is the most important part of the whole beer brewing equipment. Jinan Humber Equipment Technology Co., Ltd. has many years of production experience and a strong design team, can provide you with design equipment configuration according to your craft brewing process. Can also personalize your mash tun lauter tank brew kettle.

All our mash tun lauter tank brew kettle is made by laser cutting, automatic welding machine, automatic polishing mechanism, reliable quality and strong stability.

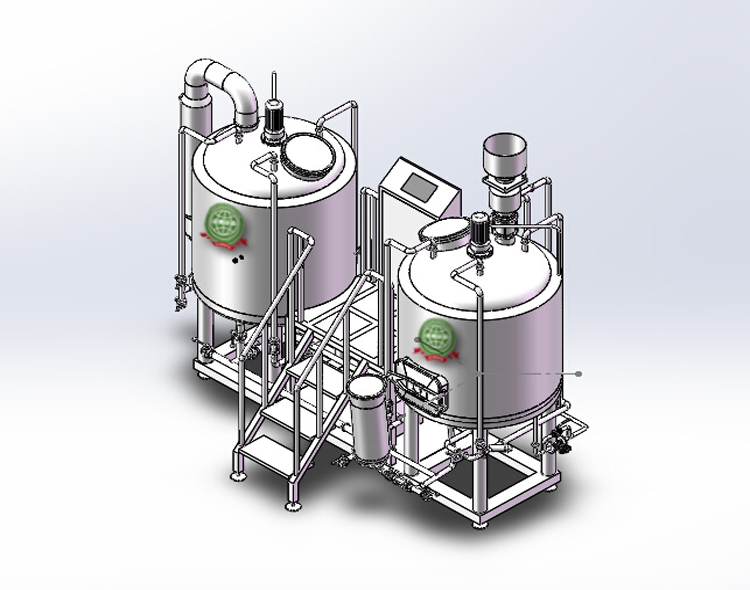

1000 Liter Mash tun Lauter tank brew kettle

As we all know, the brewhouse is the most important part of the whole beer brewing equipment. Jinan Humber Equipment Technology Co., Ltd. has many years of production experience and a strong design team, can provide you with design equipment configuration according to your craft brewing process. Can also personalize your mash tun lauter tank brew kettle.

Here is the introduce of our 1000L two vessels brewhouse:

Mash tun/ Lauter tank

Effective volume: 1000L, total volume: 1300L

Dimensions: φ1460*2720mm

Inner-Jacket(SUS304), TH=3.0mm

External-Jacket(SUS 304), TH=2.0mm

Mushroom-shaped head or dish head (SUS304), TH=3.0mm

Insulation layer: PU-thickness: 80mm.

Heating method: steam heating

Lauter tank equipped with plow knife (raker knife), power is 2.2KW (VFD controlled)

Side mounted grain outdoor with grain chute, size is 430*330mm

Easyclean and detachable sparging spray ring

Laser cutting T-wires false bottom (filter), plate gap: 0.8-1.0mm; Material is SUS 304.

Top full glass manhole: Diameter: 400mm;

Filter method: Suction filtration by speed controlled filter pump.

360° coverage CIP spraying ball

Temperature measurement way: PT100

100% TIG welded joints;

4pcs completely SUS304 heavy duty legs with leveling pad

Kettle/whirlpool tank:

Effective volume: 1000L, total volume: 1400L

Dimensions: φ1460*2720mm

Inner-Jacket(SUS304), TH=3.0mm

External-Jacket(SUS 304), TH=2.0mm;

Mushroom-shaped head or dish head (SUS304), TH=3.0mm.

Insulation layer: PU-thickness: 80mm.

Top full glass manhole: Diameter: 400mm;

Heating method: steam heating

Equipped with agitator, motor power is 1.5KW, VFD controlled.

Tangential whirlpool inlet

Glass liquid level

360° coverage CIP spraying ball

Temperature measurement way: PT100

100% TIG welded joints;

4pcs completely SUS304 heavy duty legs with leveling pad

Pumps:

Flow 5m3/h, lift 24m

Sanitary SUS304

Rev: 2880r/min Capacity:5000L/h

Centralized hard-piped manifold for liquid flow easily controlling

Power: 1.5KW

VFD controlled, open impeller

Inlet¢51, outlet¢38, tri-clamp quick-installed

Complete valves, fittings and all parts

Plate Heat exchanger

BR0.1/10㎡

Design Structure: Suspension type, screw material is SUS304, nut material is brass, easy disassembled for cleaning.

Stainless steel 304 material

Design pressure:1.0 Mpa;

Working temperature:170°.

Wort inlet and outlet diameter is φ51

Cold water inlet and outlet diameter is φ51

Tri-clamp quick-installed, single stage