10bbl Mini Beer Brewery Equipment

- HBETBREW

- Shangdong, China

- Within 50days

- 50sets/month

- Enjoy our help planing and designing your brewery project if you don't know how to do it quite well;

--- Enjoy free of charge for our debugging the brewery equipment to get it work perfectly;

--- Enjoy deciding that which port the goods will arrive at

--- Enjoy our training about how to maintain and operate the brew system personally if you are not good at it;

--- Enjoy learning some new beer production techniques from our professional brewer;

--- Enjoy our words:

1) Provide 36 months complete warranty for main parts and life-time maintenance service;

2) The seller is responsible for the nature damage of the machinery in the warranty period

except for man-made damage;

3) All spare parts and wearing parts are attached with the machinery for free.

10BBL Mini beer brewery equipment

Our malt mill machine adopt stainless steel304 or carbon steel material, have certificated CE &ISO, Advanced manufacturing technology, and with double rollers type or chrome plate type, equipped with motor, belt , belt pulley, etc, please look at the below picture:

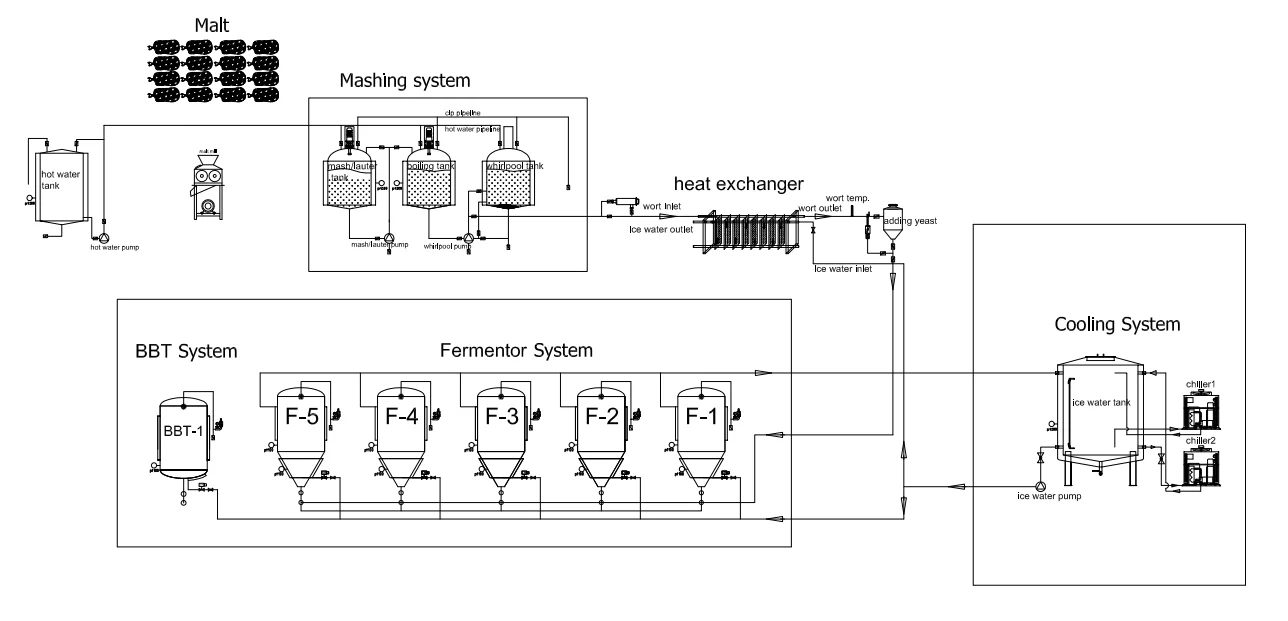

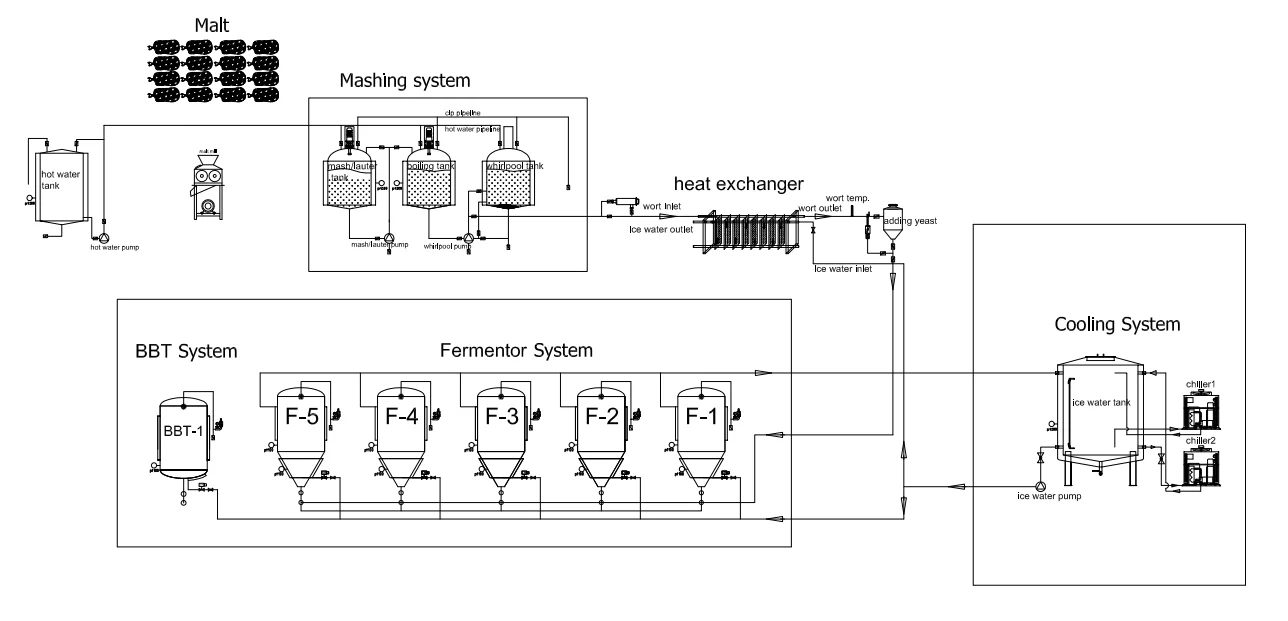

Mash tun, Lauter tun, Boiling Kettle, Whirlpool tun in various combination

Hot water tank and cold water tank for optional in special combinations

Infusion or decoction brewing methods are designed exactly

Stainless steel or copper cladding are popular

Two stages or single stage heat exchanger for wort cooling

Completely stainless steel integrated work platform

Sanitary and efficiency wort pump

All pipings and fittings

Fermenting system is consist of fermentation tank,Yeast storage tank, Ice water electromagnetic valve, Safety valve, Pressure gauge, Beer tube, Temperature probe, Temperature transmitter shell, Refrigerant piping, and valves and so on.

Fermentation Tank: the inner polished into 0.4rm, stainless steel cooling water jacket, with 1.5mm thickness.

Regarding the cooling system of brewery, normally we will equip glycol tank, chillers, and ice water pumps.

Regarding the cooling system of brewery, normally we will equip glycol tank, chillers, and ice water pumps.

Glycol tanks used for wort cooling and all fermenters / BBT / lagers cooling, this works together with two stages plate.

Besides, we also can provide the cold water tank, if so, the glycol tank just works for cooling the fermenters and cold water tank used for cooling hot wort via heat exchanger. this works together with one stages plate.

Function: Use for cleaning tanks

Component: Disinfection tank, Alkali tank (with heating element), Pump and so on. This components are significant part of beer brewing equipment.

Purpose: It is used for heating, washing, cleaning all the tanks when it finish the brewing.

PID semi-automatic controller: Simple operation, easy maintenance.

Cabinet material: stainless steel or spraying plastics;

Function: Show brewhouse tanks temperature, turn on/off all motors and pumps by button, control all fermenters/BBTs /glycol tanks temperature, chillers soft start, supply power for CIP cleaning system and so on.

PLC touch screen controller: Programmable, stable, Brewing recipes can be stored.

Cabinet material: stainless steel or spraying plastics;

Function: Show and control brewhouse tanks temperature, step heating is automatic, turn on/off all motors and pumps by touch screen, control all fermenters/BBTs/glycol tanks temperature, chillers soft start, supply power for CIP cleaning system and so on.