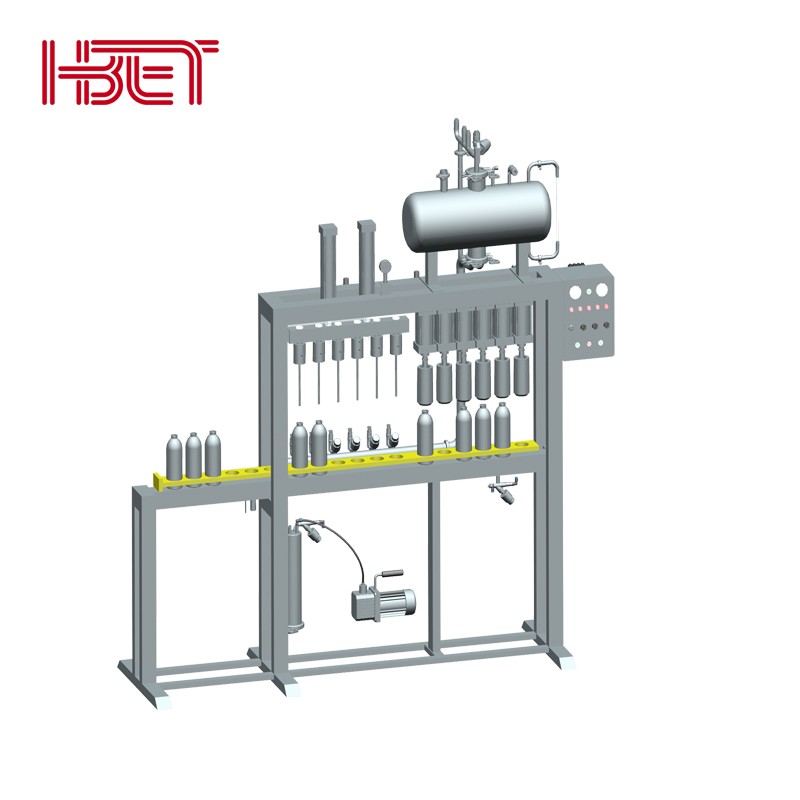

6 Heads Bottle Filler And Capper

- HBET

- Shangdong, China

- Within 30days

- 50sets/month

Our bottle filler and capper machine with automatic control by PLC, all parameters can be adjusted. Filling and capping proces can be finished by the machine at one time.

The bottle filler and capper with CO2 pressurization and vacuumization function. Adopt isobar filling method and with unique pressure maintaining system, performance stable and reliable, beer loss minimum.

With pressure compressor, to gurantee a stable filling process.

6heads bottle filler and capper

1.Main function and feature of bottle filler and capper:

1-1.Automatic control by PLC, all parameters can be adjusted.

1-2.Filling and capping proces can be finished by the machine at one time.

1-3.With CO2 pressurization and vacuumization function.

1-4.Adopt isobar filling method and with unique pressure maintaining system, performance stable and reliable, beer loss minimum.

1-5.With pressure compressor, to gurantee a stable filling process.

2.Working process of bottle filler and capper:

Fix the bottles——CO2 pressurizing——Vacuumizing——Filling——Pressure satabilization——Pressure relief——Stop——Move the bottles to the capping stations——Capping——Take the bottles

3.Main technical parameters of bottle filler and capper:

Dimensions 1800*800*2400mm

Net weight 300kg

Capacity 300-600bottles/h

Applicable bottles 330ml-2L

Working station 4-10

Power supply voltage AC 380V/50Hz(customized)

Except the bottle filler and capper, Jinan Humber Company also can supply you with the brewery and filling related equipment, such as beer brewing equipment, kegging system, labelling machine, bottle rinser and so on. Welcome to contact us for more information.