All in one semi-automatic canning system can filling machine

- HBETBREW

- Shangdong, China

- Within 30days

- 50sets/month

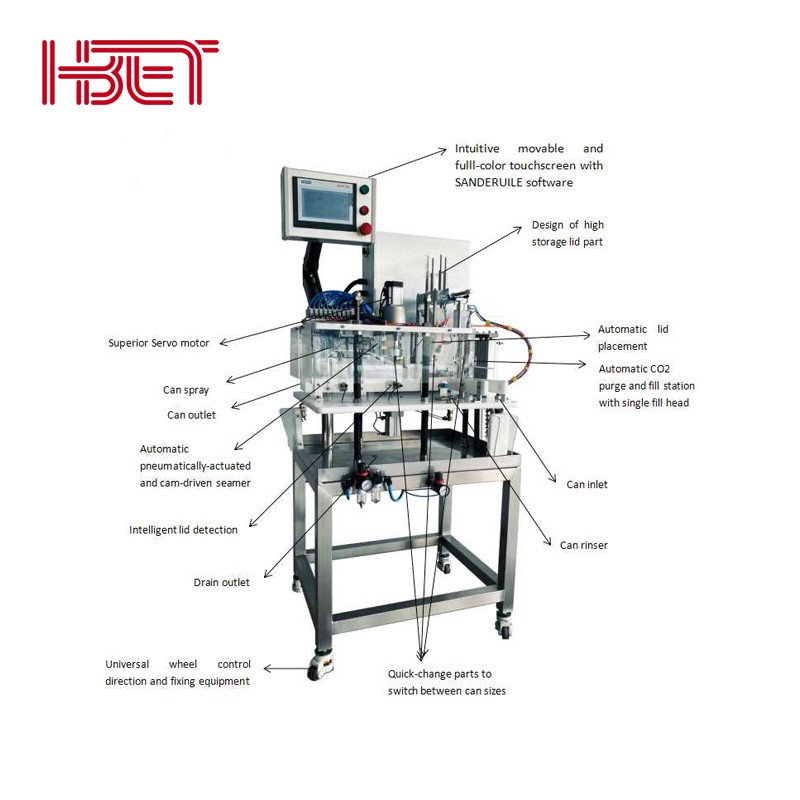

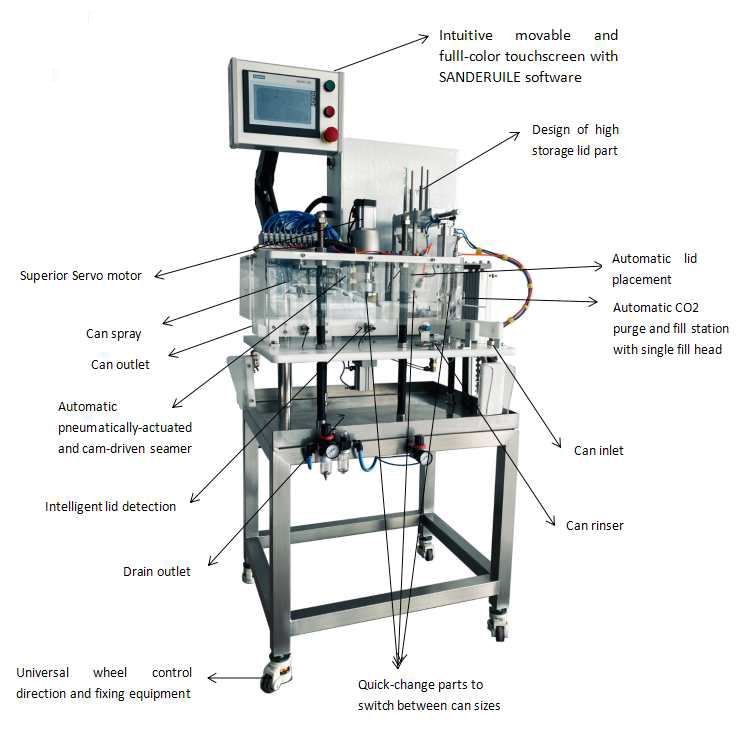

All in one semi-automatic canning system can filling machine

production capacity 500 cans per hour

Small space needed

All in one semi-automatic canning system can filling machine

All in one canning system configuration | ||

1 | Size L*W*H | 1200*730*1700mm |

2 | Weight | 133KG |

3 | Packing size L*W*H | 1450*1000*1950mm |

4 | Gross Weight | 240KG |

5 | Capacity | 500Pcs/h |

6 | Power | Single phase 110-240VAC 50/60HZ is default |

7 | Power consumption | 500W |

8 | Main Material | AISI304, Aluminum Alloy and POM |

9 | Beer source requirement | Pressure: 22psi (0.15Mpa), connection: 1.5”tri-clamp |

10 | CO2 regulator | 58-65psi (0.4-0.45Mpa) from plant system connected to canning system with 3/8”OD barbed fitting |

11 | Air regulator | 87-102psi(0.6Mpa-0.7Mpa) from plant system connected to canning system with 3/8”OD barbed fitting |

12 | Time setting way | Siemens PLC 200 smart and LEV3 touch screen |

13 | Seamer | Cemented Carbide Panasoinc Motor |

14 | Dissolved Oxygen | ≤50ppb |

15 | Can Type | Can be configured for nearly all standard can sizes, change over between different can dimensions is a snap, requiring only a few simple tools and less than 30 minutes. |

16 | Rinse function | 3S/pcs (unadjustable) |

17 | Spray function | 2S/pcs (adjustable) |

Pre-installation and commissioning instructions:

Beer requirements:

1)Temperature: 30.2 -32F (-1 to 0℃)

2)Carbonation: 2.4 to 2.7 volumes CO2 (4.6 to 5.2 g/L CO2)

3)Pressure: 22psi(0.15MPa)

4)Connection: 1.5"Tri-clamp(Ф50.5mm)

CO2 requirements:

1)22-30 psi(0.15MPa-0.20Mpa)from plant system connected to canning system with 3/8“OD barbed fitting 3/8“

Air Regulator requirements:

87-102 psi(0.6MPa-0.7Mpa) from plant system connected to canning system with 3/8“OD barbed fitting 3/8“

Reserve 16A power socket

Prepare the connection between the fermenter and the equipment. ID Ф 12-16 mm in diameter, length is less than 1 meter, 1.5 "tri-clamp on both ends and insulation.

When the ambient temperature is higher than 25℃ or when the beer pipe too long , it is recommended to add a plate for

cooling the beer pipe.

3 days before installation, the beer temperature should be reduced to the above required beer source temperature in advance to ensure that the temperature in the fermentation tank is uniform and constant.

Prepare sanitizer and cold water which for rinse the cans, interface way for 1.5 "Tri -clamp , it is recommended to use Star San.

The first commissioning shall prepare more than 500 standard lids and cans consistent with the samples provided when the contract is signed