Two In One Keg Washers And Fillers Kegging Equipment

- HBET

- Shangdong, China

- Within 30days

- 50sets/month

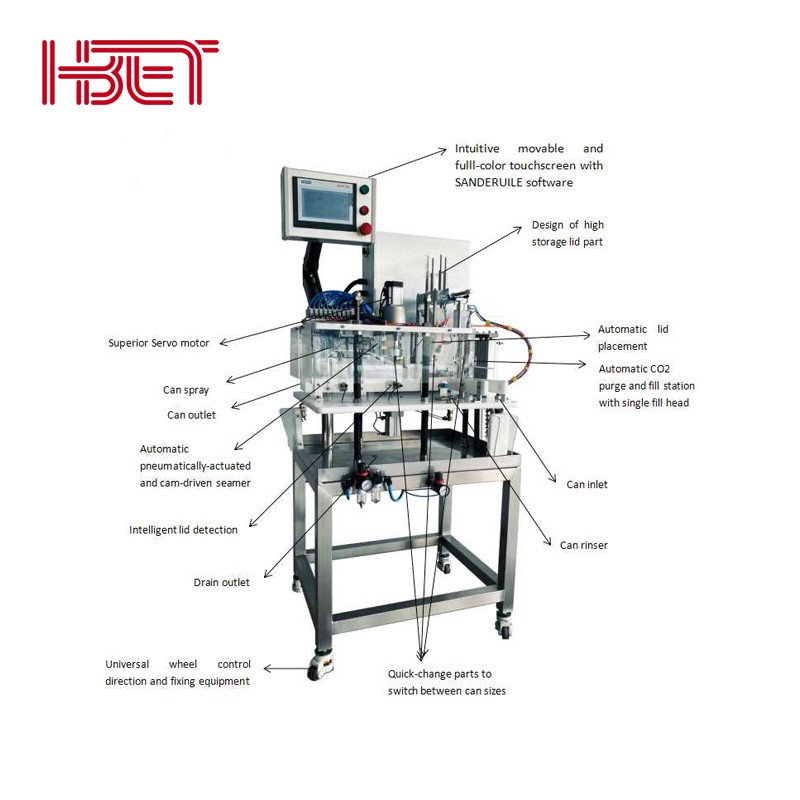

Automatic control by PLC, all parameters can be adjusted through touch screen.

Cleaning and filling process can be finished in this machine at one time.

All use pneumatic double acting Angle seat valve which could ensure the action sensitivity and reliability

With unique pressure maintaining system,performance stable and reliable, beer loss minimum.

With CIP automatic cleaning system

Two in on keg washers and fillers kegging equipment

Main Technical Parameters

Equipment Outer Dimensions | 1200*1600*2000mm |

Net Weight | 380KG |

Power | Steam Heating: 3KW Electric Heating: 18KW |

Production Capacity | 30-40 kegs/H |

Applicable Kegs | Keg with Diameter 250-500mm, Height 360-600mm |

Tank Heating Way | Electric Heating or Steam Heating |

Table Board | Fixed |

Power Supply Voltage | AC 380V 50HZ (customized) |

Working process

Filling station: Fix the keg--filling--stop--take the keg

Washing Station: Impact the keg ---Drain residue--water rinse--lye rinse--hot water rinse--steam sterilization -- Co ₂ pressurization -- Take the keg

Configurations:

PLC: Siemens S7-200 SR60

Touch Screen: Siemens 700 IE

Water Pump: YUEHUA

Heating Pipe: XIANBO

Contactor: Schneider

Breaker: Schneider

Cylinder: Air TAC

Solenoid Valve: Air TAC

Angel Seat Valve: ESG

Material: SS304

PLC: Siemens S7-200 SR60

Main function and feature

1、Automatic control by PLC, all parameters can be adjusted through touch screen.

2、Cleaning and filling process can be finished in this machine at one time.

3、All use pneumatic double acting Angle seat valve which could ensure the action sensitivity and reliability

4、With unique pressure maintaining system,performance stable and reliable, beer loss minimum.

5、With CIP automatic cleaning system