10bbl Brewery For Sale

- HBETBREW

- Shandong China

- 40working days

- 10sets per month

ONE-STOP SERVICE FOR YOUR BREWERY PLANT

Jinan Humber Equipment Technology Co., Ltd is one professional micro brewery equipment manufacturer in China with many years production and installation experience, passed ISO, CE PED approval and can supply the complete trunkey beer/wine brewery equipment from 50L to 500000L/batch system for you.

10bbl Brewery For Sale

ONE-STOP SERVICE FOR YOUR BREWERY PLANT

Jinan Humber Equipment Technology Co., Ltd is one professional micro brewery equipment manufacturer in China with many years production and installation experience, passed ISO, CE PED approval and can supply the complete trunkey beer/wine brewery equipment from 50L to 500000L/batch system for you.

Mashing system

Brewhouse

Function: Grain mashing, wort filtration, boiling, and whirlpooling.

Component: It is composed of mash tun, lauter tank, kettle, whirlpool, hot water tank, hops back, plate heat exchanger with oxygenation device, wort pump and etc. It is the second part of micro beer brewing equipment.

Types: 2 Vessels brewhouse, 3 Vessels brewhouse, 4 Vessels brewhouse

Heating method: Electric heating, Steam heating, Direct fire heating.

Control method: PLC Screen controller cabinet or PID Instrument Panel.

Material: Food and sanitary grade stainless steel 304/316, Luxury red copper.

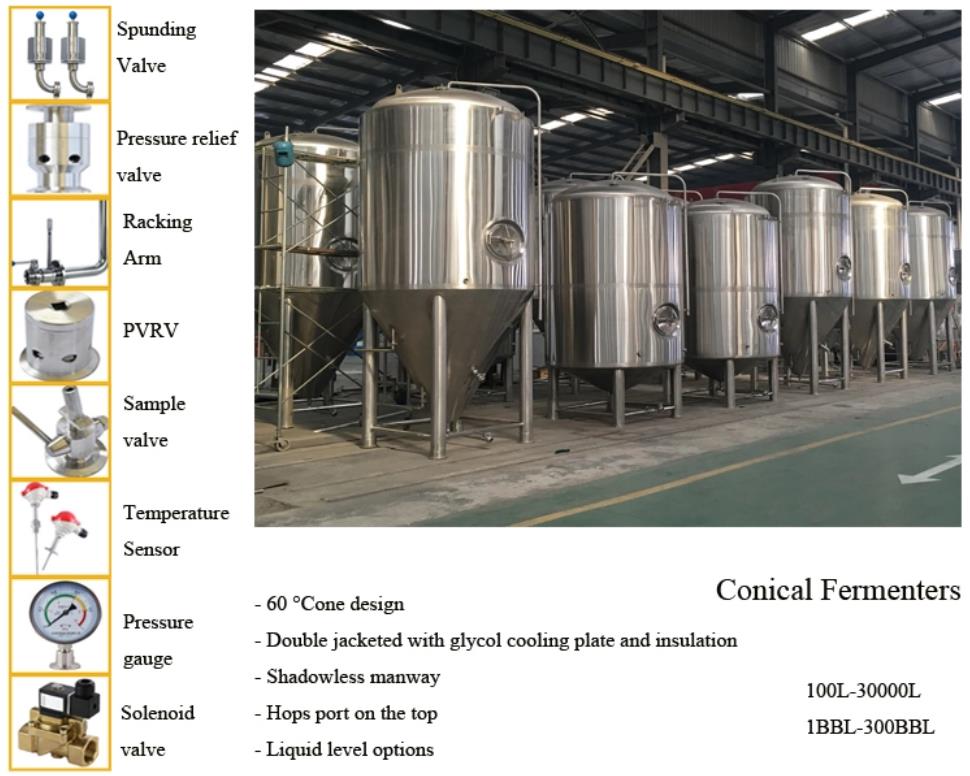

Fermentation system

Fermentation tank

Function: Wort fermentation or maturtion.

Component: It is composed of Shadowless manhole, Pressure relief valve, Aseptic valve, Pressure gage, Rotate racking arm, Butterfly valve, Pressure relief valve and so on. It is the third part of micro beer brewing equipment.

Types: 50L-10000L, and even bigger volume.

Cooling method: Ice water belt or glycol cooling jacket around both top and bottom.

Design pressure is 0.3MPa; Working pressure is 0.15MPa.

Material: Stainless steel 304/316/316L.

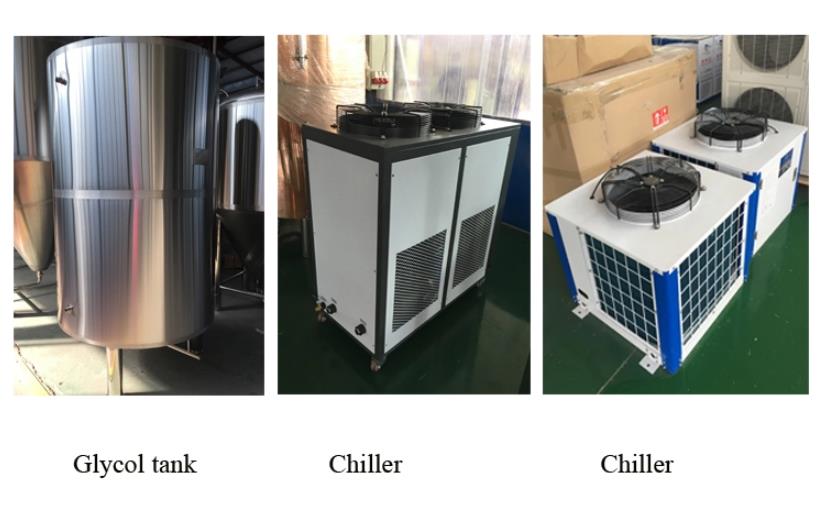

Glycol cooling system

Glycol water tank

Function: Glycol water supply for wort cooling and fermentation cooling.

Component: Glycol water tank, Solenoid valve, Pump, PPR and etc. It is the fourth part of thestainless steel 304 beer brewing equipment.

Cooling method: Single stage cooling (cold water cooling) and Two stage cooling (Glycol water and tap water cooling).

Control method: Automatically by PID/PLC Controller cabinet.

Tips: ( single stage cooling)

Some experienced brewers prefer cold liquor tank(cold water tank) for cooling the wort in the heat exchanger. The wort can be cooled much quicked than before. Accordingly, the cold water would also be heated to a high temperature. In this case, the cold water passing the heat exchanger would be recycled to hot water tank directly. This kind flow can save much energy.

The most important advantage is the wort would not be polluted when the heat exchange is broken.

COOLSOON Chiller

Function: Glycol water chilling

Chiller brand: World famous Australia COOLSOON.

Component: Compressor, Water pump, Evaporator, Pressure controller, Condenser, LCD temperature controller, Expansion valve, Dry filter, Hand valve, Draught fan and so on. It is the fifth part of the beer brewing equipment.

Advantages: Work highly efficient, Cooling faster and stable, If there have something wrong in the future, it is very easy to find spare part in anywhere.