Brewpub Brewery Equipment

- HBETBREW

- Shangdong, China

- Within 50days

- 50sets/month

Jinan Humber equipment technology co., ltd is one professional brewery equipment manufacture in China. We specialize in personally manufacturing small, medium and big sized brewery plants. We also manufacture all types and sizes of fermenting and storage tanks. Our breweries can be designed according to the specific wishes of our customers. We also can offer you a wide variety of technical solutions. We can provide beer to make by fermentation of the equipments of having, can train to make wine teacher.

We can supply 50L,100L, 200L, 300L, 500L, 1000L, 2000L, 3000l, 5000l capacity brewery equipment. And customize according to your requirements.

Brewpub Brewery Equipment

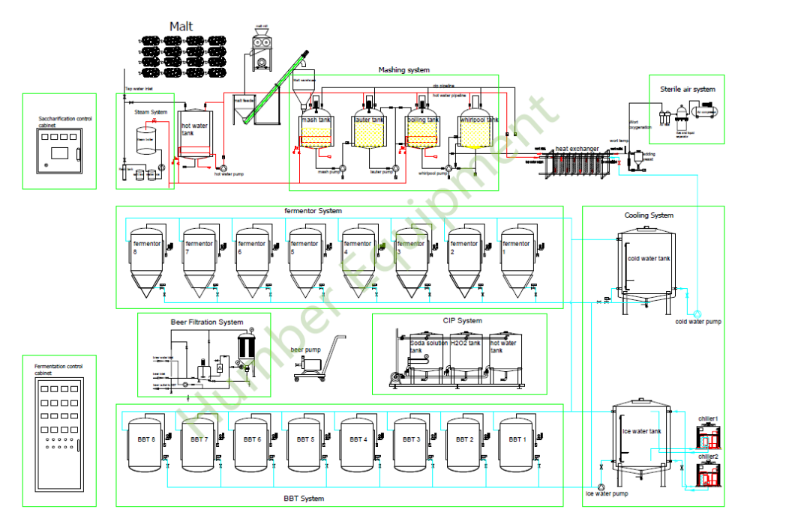

Milling:

Milling:

Here, malt is grinded and malt husks are cracked. It makes mashing faster and makes filtration of mashing easier.

Mashing:

Mashing is the process of mixing milled malt and water, then heat this mixture. Mashing allows the enzymes in the malt to break down the starch in the grains into sugars. Mashing involves pauses at certain temperature(notably 45-62-73℃ or 113-144-163℉). Mashing takes place in mash kettle.

Lautering:

Lautering is the separation of grains and liquid. The bottom of lautering kettle has thin slits to hold back the solids and allow liquids to pass through. The mash itself functions as a sand filter to capture mash debris and proteins through recirculation. Grain washing also takes place in the lautering tank. After the wort runs-off, trickling water will goes through the grain to extract sugars.

Boiling:

After lautering, the wort will be boiled with hops ( and other flavouring if needed). Average boiling time ranges from 45 to 90 minutes, depending on its intensity, the hop addition schedule and water volume.

Whirlpool:

At the end of the boil, solid particles in the hopped wort are separated from whirlpool tank. Then wort will be cooled when runs into the fermentation tank through the plate heat exchanger.

Fermentation:

It takes place in fermentation tank. Sugar in wort will be transformed into ethyl alcohol by respiratory action of yeast. At same time, some other chemical and physical reaction happens too. Wort turns into beer gradually under these reactions.

After fermentation, we can drink beer directly or put beer into BBT via filtering equipment.

These processes are finished in several tanks. Tank quantity can be customized.