Chiller For Beer Brewery

- HBETBREW

- Shangdong, China

- Within 30days

- 50sets/month

Imported branded compressor from USA and Japan, built in safety protection, low noise, power-saving and durability.

Italian water pump with big flow, high efficiency and durability.

Widely used in plastic industry, electrons, plating chemical industry, ultrasonic wave cooling, printing and others. It can precisely control the temperature, whcih is requested by the modernized machinery production.

Chiller for beer brewery

Model: CA-05L

Refrigerating Capacity: 6364 Kcal/h Power: 7.4KW

Input General Power: 4.86KW

Power Source: 3PH-380V/50HZ Refrigerant Name: R22

Control Method: External balance type thermostatic expansion valve Compressor Type: Fully enclosed scroll (piston)

Power: 3.75KW

Condenser type: High efficiency copper tube aluminum fin+Low noise external rotor fan Condenser Cooling Air Volume: 5000m3/h Evaporator Type: Plate type

Frozen Water Volume: 2.22m3/h

Water inlet and outlet pipe diameter: 1" Pump power: 0.75KW; Lift: 20m

Safety refinements: Compressor overheating protection, Overcurrent protection, High and low pressure protection, Over-temperature protection, Flow protection, Phase sequence/phase protection, Exhaust overheating protection

Weight: 175KG

Size: 1140*560*1040mm

Remarks:

1.Refrigerating Capacity Basis: -10℃, Chilled water inlet and outlet water temperature is -5℃/-10℃; -20℃, Chilled water inlet and outlet water temperature is -15℃/-20℃; -30℃, Chilled water inlet and outlet water temperature is -25℃/-30℃, Input and outout cooling air temperature is 30℃/38℃.

2.Working Range: Chilled water temperature range:-5℃ to 35℃; Difference of inpout and outout chilled water: 3℃ to 8℃, In the condensation temperature is not higher than 35 ℃ environment

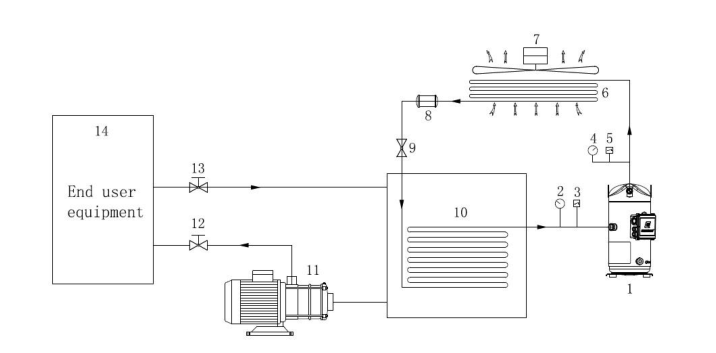

Internal structure schematic diagram of the air cooled chiller:

1.Compressor

2.Low pressure gauge

3.Low pressure protector

4.High pressure gauge

5.High pressure protector

6.Condenser

7.Cooling fan

8.Dry filter

9.Capillary(Expansion valve)

10.Evaporator

11.Cold water pump

12.13.Water flow switch

Notes for operation of chiller:

The refrigerating water pump should not work if there is no water in the water tank; (For the chiller unit above 7.5 HP, there is a built-in water level protector in the water tank. While the water level is too low or the tank is empty, the water pump will be stopped automatically, and it displays

the water-level fault code and alarm.)

The operating switches should be avoided frequently switching over. Pls turn off the main power when the machine did not work for a long time.

While the refrigerated-water temperature reaches to the set temperature, the compressor will stop.

In order to prevent the evaporator freezing, do not set temperature below 5℃;( except the low temperature chillers), Pls drain out the chilled medium off the machine when it did not work for a long time.

To make sure the best cooling efficiency and best working condition of the unit, please clean the condenser, evaporator and the water filter regularly, and confirm there are no adulterant and other obstruction.

Please turn off chiller as long as if it is alarming. And start chiller after the failures are removed according to the way stated as item 7 and item 10. Or you can contact with our after-sale service staff shortly.