Turnkey Solution For Beer Brewing

- HBETBREW

- Shandong, China

- 40 working days

- 20sets/month

In order to ensure the quality of our beer brewing equipment, our company has introduced spectrometers, thickness gauges and roughness testers. Through these testing equipments, we strictly control the quality of raw materials, production and processing details of our products, and provide customers with professional high quality products. Welcome to visit us and inspect the equipment in person.

Turnkey solution for beer brewing

Jinan Humber Equipment Technology Co., Ltd is one professional beer brewing equipment manufacturer in China with many years production and installation experience, we can supply you the complete brewery equipment from grains handing to packaging.

Miller of beer brewing equipment:

- Grain Miller:

Crushing ability:150-2000kg/h

Application: Used for grain mill

Material:SUS304 and carbon steel

With Double rollers, the distance can be adjustment;

New design, reduce malt residue automatically

With explosion-proof motors; Low Noise.

Auger:

Used for transporting the grains from miller to hopper;

Material: SUS304

Economize on manpower for bigger brewery systems;

Hopper:

Placed on the top of mash tun, stainless steel 304, used for store the grains. 0.6m3, 0.8m3, 1.0m3, 1.2m3, 1.2m3,…….

Mashing System of Beer Brewing Equipment:

Brewhouse

Function: Grain mashing, wort filtration, boiling, and whirlpooling.

Component: It is composed of mash tun, lauter tank, kettle, whirlpool, hot water tank, hops back, plate heat exchanger with oxygenation device, wort pump and etc. It is the second part of micro beer brewing equipment.

Types: 2 Vessels brewhouse, 3 Vessels brewhouse, 4 Vessels brewhouse

Heating method: Electric heating, Steam heating, Direct fire heating.

Control method: PLC Screen controller cabinet or PID Instrument Panel.

Material: Food and sanitary grade stainless steel 304/316, Luxury red copper.

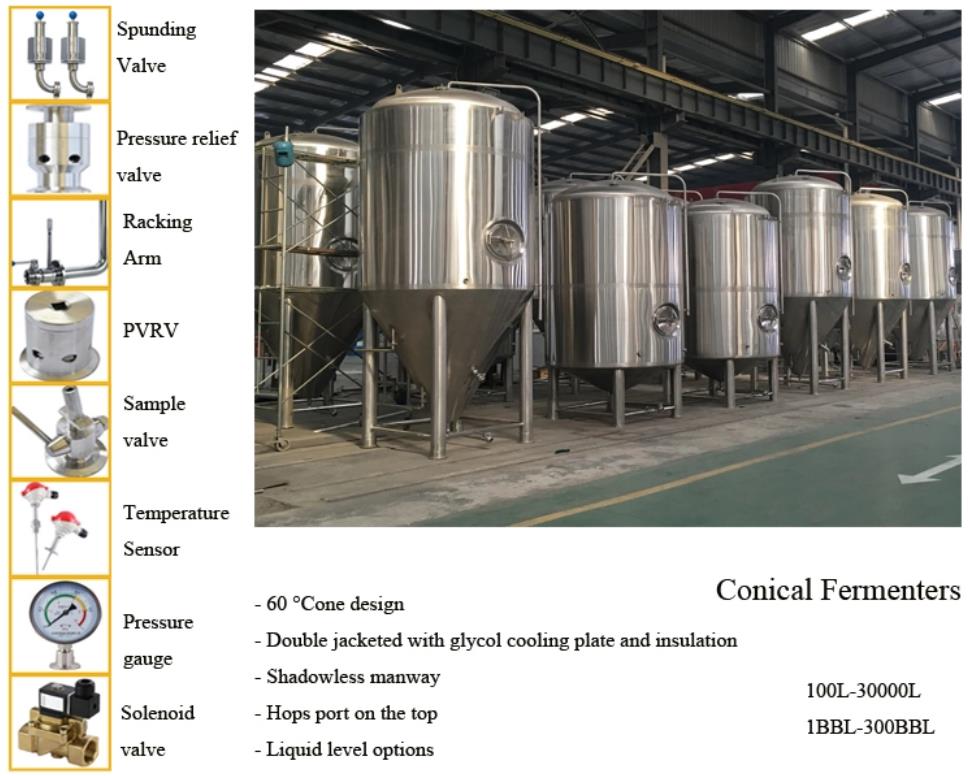

Fermenters of beer brewing equipment:

No. | Item | Introduction |

01 | Volume | 100L-50000L or even bigger |

02 | Material | Stainless steel 304 or 316 |

03 | Insulation | Polyurethane, TH: 80-100mm |

04 | Fermentation tank | |

05 | Dish Head | Double or single dish head on the top |

06 | Accessories |

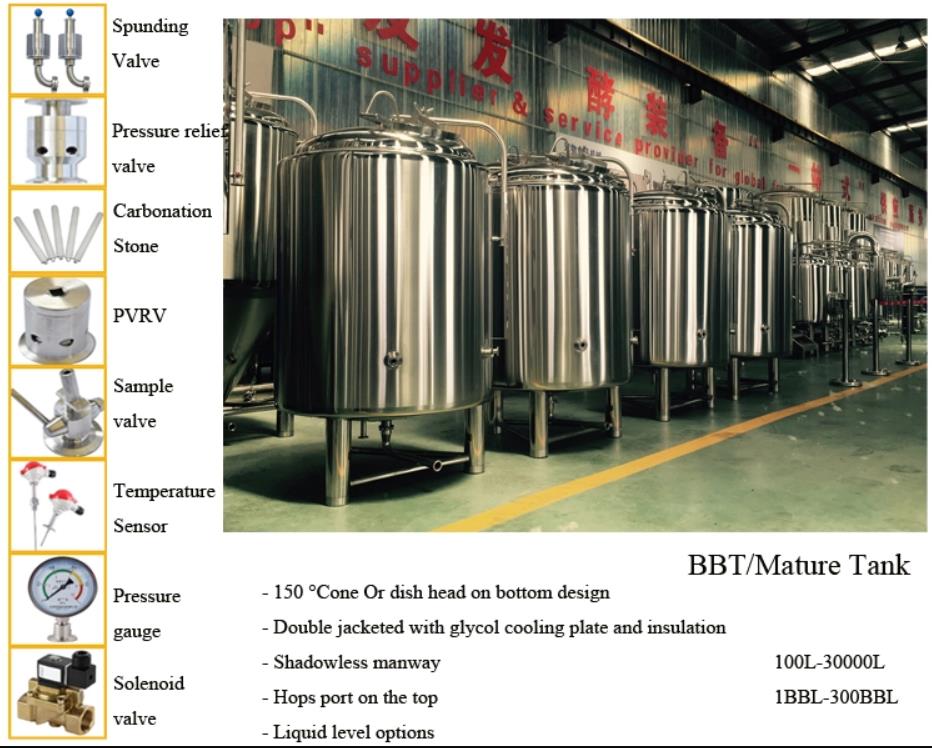

BBT of beer brewing equipment:

01 |

Volume |

100L-50000L or even bigger |

02 | Material | Stainless steel 304 or 316 |

03 | Insulation | Polyurethane, TH: 80-100mm |

04 | Fermentation tank | |

05 | Dish Head | Double or single dish head on the top |

06 | Accessories |

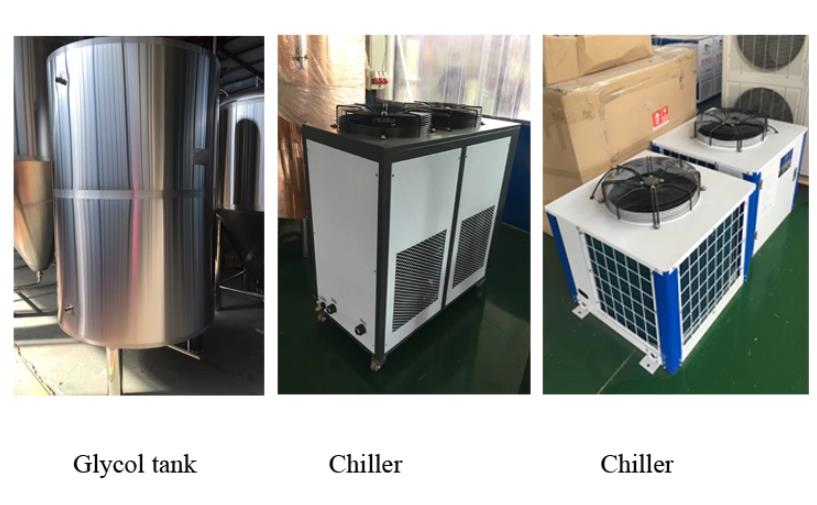

Cooling system of beer brewing equipment:

No. | Item | Introduction |

01 | Glycol water tank | |

02 | Chiller | According to glycol water tank's capacity |

World famous brand--Australia COOLSOON, the quality is highly excellent, cooling efficient is the best. If there have something wrong in the future, it is easy to find spare part. | ||

03 | Function | Glycol water tank and Chiller will work rogether, to keep cooling wort in the plate heat exchanger. |

Welcome to contact us for more information of beer brewing equipment.