| Medium temperature [°C] | -10...70 |

| Pressure rating [bar] | 16 |

| MAWP (for applications according to CRN) [bar] | 11.2 |

| Electrical data |

|---|

| Operating voltage [V] | 18...30 DC; (according to EN 50178 SELV/PELV) |

| Current consumption [mA] | 95; (24 V) |

| Protection class | III |

| Reverse polarity protection | yes |

| Power-on delay time [s] | 5 |

| Inputs / outputs |

|---|

| Number of inputs and outputs | Number of digital outputs: 2; Number of analog outputs: 1 |

| Inputs |

|---|

| Inputs | counter reset |

| Outputs |

|---|

| Total number of outputs | 2 |

| Output signal | switching signal; analog signal; pulse signal; IO-Link; (configurable) |

| Electrical design | PNP/NPN |

| Number of digital outputs | 2 |

| Output function | normally open / closed; (configurable) |

| Max. voltage drop switching output DC [V] | 2 |

| Permanent current rating of switching output DC [mA] | 200 |

| Number of analog outputs | 1 |

| Analog current output [mA] | 4...20; (scalable) |

| Max. load [Ω] | 500 |

| Analog voltage output [V] | 0...10; (scalable) |

| Min. load resistance [Ω] | 2000 |

| Pulse output | flow rate meter |

| Short-circuit protection | yes |

| Type of short-circuit protection | yes (non-latching) |

| Overload protection | yes |

| Measuring/setting range |

|---|

| Measuring range | | 0.2...100 l/min | 0.01...6 m³/h |

|

| Display range | | -120...120 l/min | -7.2...7.2 m³/h |

|

| Resolution | |

| Set point SP | | 0.7...100 l/min | 0.04...6 m³/h |

|

| Reset point rP | | 0.2...99.5 l/min | 0.01...5.97 m³/h |

|

| Analog start point ASP | |

| Analog end point AEP | | 20...100 l/min | 1.2...6 m³/h |

|

| In steps of | |

| Volumetric flow quantity monitoring |

|---|

| Pulse value | 0.00001...100 000 m³ |

| Pulse length [s] | 0,0025...2 |

| Temperature monitoring |

|---|

| Measuring range [°C] | -20...80 |

| Resolution [°C] | 0.2 |

| Set point SP [°C] | -19.2...80 |

| Reset point rP [°C] | -19.6...79.6 |

| Analog start point [°C] | -20...60 |

| Analog end point [°C] | 0...80 |

| In steps of [°C] | 0.2 |

| Accuracy / deviations |

|---|

| Flow monitoring |

|---|

| Accuracy (in the measuring range) | ± (0,8 % MW + 0,5 % MEW) |

| Repeatability | ± 0,2% MEW |

| Temperature monitoring |

|---|

| Accuracy [K] | ± 2,5 (Q > 5 l/min) |

| Reaction times |

|---|

| Flow monitoring |

|---|

| Response time [s] | 0.15; (dAP = 0, T19) |

| Delay time programmable dS, dr [s] | 0...50 |

| Damping for the switching output dAP [s] | 0...5 |

| Temperature monitoring |

|---|

| Dynamic response T05 / T09 [s] | T09 = 20 (Q > 5 l/min) |

| Software / programming |

|---|

| Parameter setting options | Flow monitoring; quantity meter; Preset counter; Temperature monitoring; hysteresis / window; normally open / closed; switching logic; current/voltage/pulse output; Start-up delay; display can be deactivated; Display unit |

| Interfaces |

|---|

| Communication interface | IO-Link |

| Transmission type | COM2 (38,4 kBaud) |

| IO-Link revision | 1.1 |

| SDCI standard | IEC 61131-9 |

| IO-Link device ID | 575 / 00 02 3f |

| Profiles | Smart Sensor: Process Data Variable; Device Identification, Device Diagnosis |

| SIO mode | yes |

| Required master port class | A |

| Process data analogue | 3 |

| Process data binary | 2 |

| Min. process cycle time [ms] | 5 |

| Operating conditions |

|---|

| Ambient temperature [°C] | -10...60 |

| Storage temperature [°C] | -25...80 |

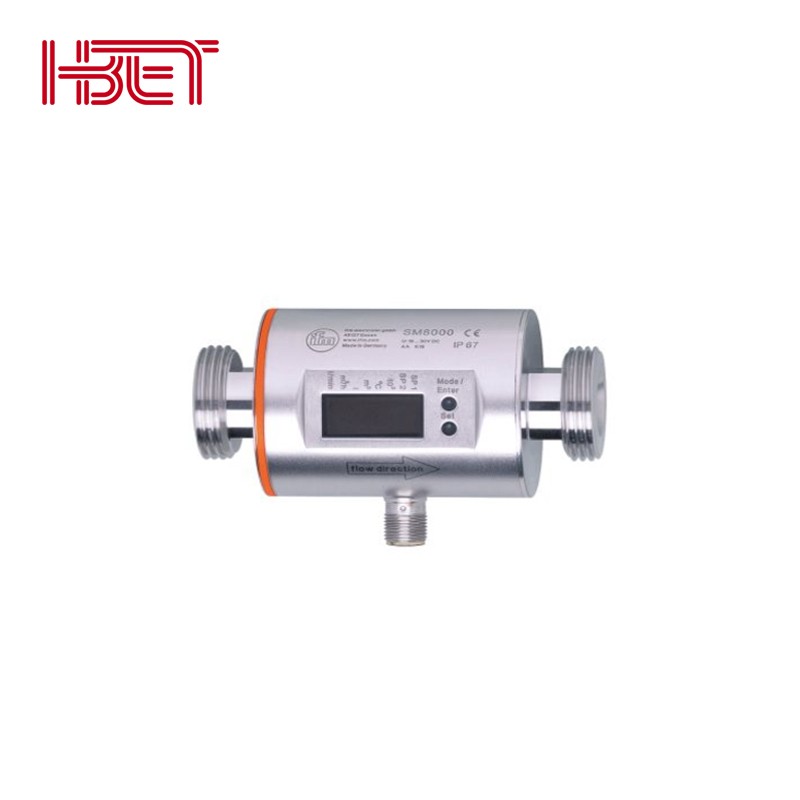

| Protection | IP 67 |

| Tests / approvals |

|---|

| EMC | |

| Shock resistance | | DIN IEC 68-2-27 | 20 g (11 ms) |

|

| Vibration resistance | | DIN IEC 68-2-6 | 5 g (10...2000 Hz) |

|

| MTTF [years] | 145 |

| Pressure equipment directive | sound engineering practice; can be used for group 2 fluids; group 1 fluids on request |

| Mechanical data |

|---|

| Weight [g] | 641.5 |

| Material | stainless steel (1.4404 / 316L); PBT-GF20; PC; FKM; TPE |

| Materials (wetted parts) | stainless steel (1.4404 / 316L); PEEK; FKM |

| Process connection | threaded connection G 1 DN25 flat seal |

| Displays / operating elements |

|---|

| Display | | Display unit | 6 x LED, green (l/min, m³/h, l, m³, 10³, °C) | | Switching status | 2 x LED, yellow | | Measured values | alphanumeric display, 4-digit | | Programming | alphanumeric display, 4-digit |

|

| Remarks |

|---|

| Remarks | | MW = Measured value | | MEW = Final value of the measuring range |

|

| Pack quantity | 1 pcs. |

| Electrical connection |

|---|

| Connection | Connector: 1 x M12; Contacts: gold-plated |