Steam Boiler For Brewhouse

- HBET

- Shangdong, China

- Within 30days

- 50sets/month

Fully automatic electrical heating steam generator is the ideal steam source for garment washing and food processing industry. It's featured by compact structure, small size and convenient for use, ect and applies to all units which need small amount of low-pressure steam.

This series of steam boiler are composed of boiler furnace, heater, water supply system, control system and shell.

Steam boiler for brewhouse

Jinan Humber Equipment technology Co., ltd is one professional micro brewery equipment manufacturer in China, expect the brewery, we also can supply the brewery related equipment. especially about the steam heating system for brewery.

Introduction of main parts and functions of steam boiler:

(1). Boiler body: It's the pressure element of boiler. See the nameplate for the details of the pressure it can bear. Electrical heater is located on the top of boiler.

(2). Heating pipe: Electrical heating pipe is the heating device of boiler. It can heat water and make water become steam within specified time limit. Its heating part is submerged into water completely, so thermal efficiency is very high.

(3). Electrical control panel: It's located in the front of boiler and is the heart of boiler. It has the functions like automatic water intake, automatic heating, automatic protection, low water level alarm, overpressure protection and electricity leakage protection.

(4). Water pump: It's the water supply device of boiler. It can supplement water automatically if boiler lacks water or has no water. There are two check valves behind the pump, which can control the backflow of water in boiler. Main reason for backflow of hot water in boiler is check valve failure, so check valve should be replaced in time, otherwise the boiled water will damage the

sealing ring of pump, thus causing water leakage of pump. Section 1 Product Introduction 2

(5) Pressure controller: It's an electro-mechanical converter that converts pressure signal into electrical switching signal. It can output switching signal under different pressures. Manufacturer has regulated the pressure properly before delivery.

(6). Water level electrode: It's an important component for water level control of boiler and realizes the automatic control of water level using the difference of conductivity between water and steam.

(7). Safety valve: It's a safety protection device of boiler. After boiler starts up, if boiler cannot stop operating under the set pressure for various reasons and pressure in boiler exceeds the set pressure, the safety valve will open automatically to discharge pressure and reduce pressure in boiler, thus

achieving the purpose of protecting the safe operation of boiler. In order to prevent valve disk of safety valve from sticking to valve seat, steam exhaust test should be conducted by pulling the safety valve lift lever regularly. Steam exhaust test should be conducted by increasing the steam pressure once every 2-4 weeks to verify the effect of safety valve.

(8). Blowdown valve: It's installed on the bottom of boiler and can eliminate the dirt in boiler thoroughly. If it's in use, the pressure should not be more than 0.1mpa.

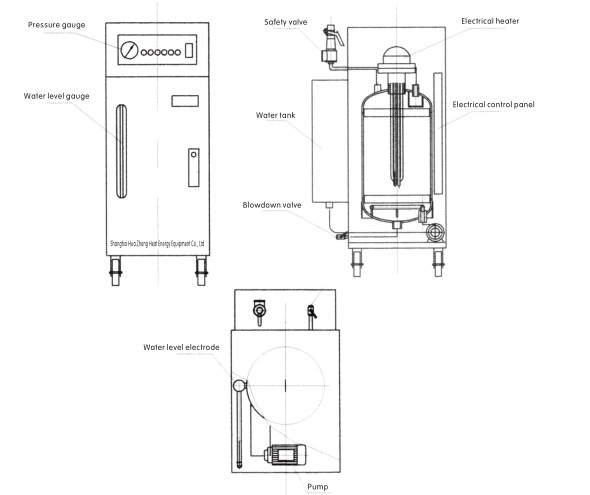

Schematic diagram of main parts of boiler:

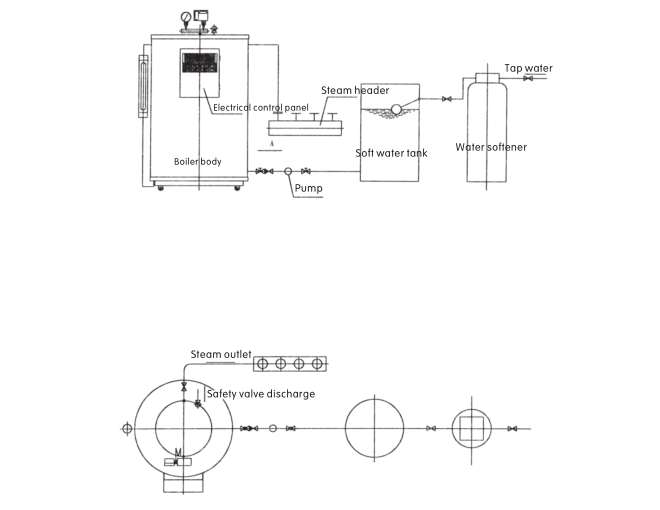

Schematic Diagram of Installation of Electrical Heating Boiler: